Welcome to the Plastic IQ Solutions Database,

a guide to technologies, strategies, and best practices for reducing plastic waste

CHOOSE YOUR SOLUTION

Eliminate plastic items

Minimize plastic

per item

Reuse models

Paper

Compostables

Glass

Metal

More recyclable formats

Enhance

recyclability

Bio-based content

Mechanically

recycled content

Chemically

recycled content

Bio-based content

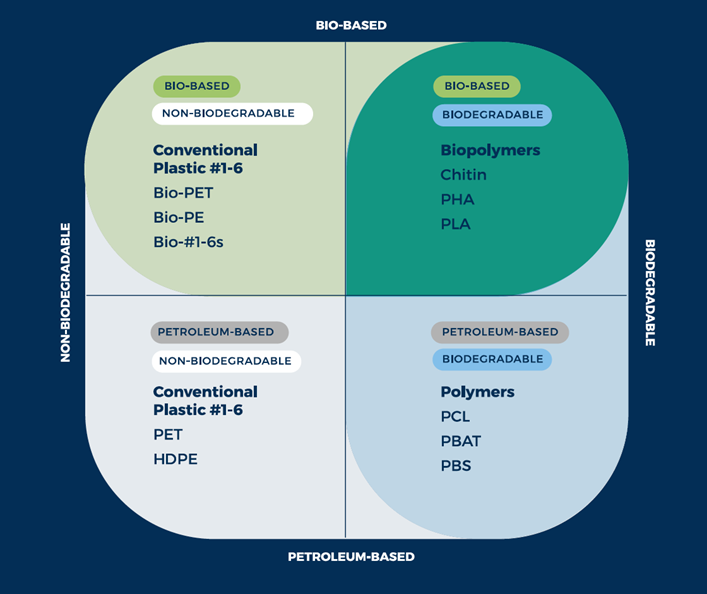

Using bio-based plastics creates another pathway to transition away from fossil fuel-based, finite resources. In making this shift, it is critically important to make sure that the sourcing of raw materials for bio-based plastics is done sustainably and does not generate unintended consequences or impacts related to land use, such as competition for food, water usage, or soil degradation. Bio-based plastics are also still considered virgin material and do not contribute to the “virgin plastic reduction” goals stated in the Ellen MacArthur Foundation’s Global Commitment, the U.S. Plastics Pact, or final targets submitted to Plastic IQ.

Bio-based plastics are made from plant-based or animal-based feedstocks rather than from fossil fuels such as oil or natural gas. However, bio-based plastic content is not the same as biodegradable and does not mean that the plastic biodegrades in nature. In fact, many bio-based plastics have the same degradability as fossil fuel-based plastics.

Some bio-based plastics are “drop-in” plastics that have the same chemical composition as their fossil fuel-based equivalents and can be used and recycled in the same manner. These plastics are generally neither compostable nor biodegradable. For example, bio-based polyethylene (LDPE/HDPE/PE) has identical properties to fossil fuel-based polyethylene but is derived from sugarcane.

Other (“non-drop-in”) bio-based plastics are different from the common fossil fuel-based plastics used in packaging (such as HDPE or PET). These plastics are not recyclable in most mechanical recycling systems and may contaminate the recycling system. In some formats, they can be either industrially compostable or home compostable where they have been certified against established compostability standards.

This complexity of bio-based materials creates confusion for consumers, policymakers, and other stakeholders. But the appropriate use of bio-based materials can create environmental benefits and play an important pioneering role in the circular economy.

The target of the U.S. Plastics Pact is for 30% of plastic to be made from either bio-based or recycled content by 2025. In all circumstances, the cultivation of bio-based feedstocks could have unintended environmental or social consequences (e.g., food competition), so sustainable sourcing is essential.

Bio-based “drop-in” content is most widely available for PE, PP, and PET. As “drop-in” plastics are chemically identical to traditional plastics, the main limits on their use are availability and potential costs. The supply of bio-based plastic is currently still limited. Companies should work with suppliers to evaluate the feasibility of using bio-plastics and their availability. Bio-based alternatives that are not “drop in” should be used more carefully because they can contaminate recycling systems. Certified compostable plastics should always be used in applications in which their disposal could add value to the system. One such example is the use of bio-based plastics that are certified as compostable and can be easily discarded with food waste, where there is a food waste collection and composting system in place that accepts them. It should be recognized that industrial composting access in the U.S. is currently extremely limited, so prior to switching to a compostable bio-plastic, companies should understand the local infrastructure of where the product will be used. See the Substitution solution lever on “compostable materials” for further information on compostability.

Greenhouse gas (GHG) emissions associated with bio-based plastic “drop-in” feedstock can vary depending on the plastic type, feedstock, geographical region, and the energy sources used in refineries. Studies vary significantly but, in general, bio-PE and bio-PP tend to perform better than bio-PET relative to fossil fuel-based alternatives. The performance of bio-based plastic producers will likely continue to improve over time as they reach more mature commercialization scales and enact continuous improvement plans.

Aside from GHG emissions, burden shifting to different environmental impacts than for fossil fuel-based plastics can be a risk of bio-based plastics, in particular regarding the additional amounts of land and water use needed, increasing competition for different land uses, and negative effects on biodiversity. Other environmental impacts can also be caused by the agrochemicals used in agricultural production (1). Companies should better understand these potential trade-offs as they consider using bio-based plastics.

Interrelationship between conventional, bio-based and biodegradable plastics. Source: Closed Loop Partners “Navigating Plastic Alternatives in a Circular Economy,” 2021.

- Potential for reduced GHG emissions: Sourcing bio-based plastics may reduce GHG emissions compared to fossil fuel-based equivalents. Sustainably managed (renewable) plant feedstocks should grow back and absorb the same amount of carbon dioxide as is released when the plastic reaches its end of life. Bio-based plastics could have a net-positive impact, as in the best-case scenario where the bio-based plastic is recycled and substitutes fossil fuel-based plastic production in its second life.

Reduced fossil fuel extraction and consumption: Sourcing bio-based plastics can reduce the extraction and consumption of fossil fuels. In addition to the GHG emission reductions noted above, this provides new pathways to decouple material systems from fossil fuel extraction.

Satisfying consumer preference: Bio-based materials may be preferred by some consumers, who are increasingly concerned about the environmental performance of packaging. Companies are encouraged to test the consumer response to bio-based packaging compared to fossil fuel-based packaging.

Reduced plastic waste and increased composting: If certified as home-compostable or industrially compostable, certain bio-based plastics can be disposed in composting systems. In that way, those plastics can reduce plastic waste and potentially increase the recovery of food waste for composting, avoiding GHG emissions that would have been generated by disposal in landfills.

- Join collaboratives: The WWF Bioplastic Feedstock Alliance provides thought leadership and a convening mechanism to advance the knowledge of bio-plastics and their potential impacts (4). The Sustainable Packaging Coalition offers a course on bio-plastics in packaging and routinely covers topics on bio-plastics in conferences and other educational forums (5).

Use established guidelines: The Biodegradable Products Institute published guidelines to help the labeling and identification of compostable products and packaging. Standards from specialists – including the Roundtable on Sustainable Biomaterials (RSB), ISCC+, and REDCert – can be used to assure companies and customers that materials are sourced responsibly and tracked through the supply chain with a robust chain of custody standard.

Work with suppliers to evaluate options: By working with suppliers, you can evaluate options and applications that are best suited for your packaging application.

Seek assurance for sustainable land use: Whether the feedstock material is derived from a farm or a forest, it is important to make sure that the practices used do not have detrimental impacts on people or the planet. WWF’s Bioplastic Feedstock Alliance developed a Methodology for the Assessment of Bioplastic Feedstocks that describes five foundational goals for feedstock sourcing, supported by specific indicators (6).

- Stakeholder education: Consumer research and education will be necessary to determine how to best celebrate the use of bio-based materials without confusing people by conveying the message that materials are compostable in cases where they are not.

Policy and standards: Federal and state policy incentives could help finance the development of bioplastics and strengthen markets. While USDA federal procurement guidelines have been in place since 2002, these programs are still in nascent stages (7).

Industrywide checkoff program: The USDA has a methodology for governing voluntary, industrywide “checkoff” programs for environmental commodities (8). Checkoff campaigns are industry-funded marketing programs that have proven successful for a wide range of commodities, ranging from milk and cotton to paper and lumber. A new checkoff program for bio-based plastics could provide resources for advertising, market research, and consumer education.

References and further reading

(1) Brizga, J., Hubacek, K., Fenga, K. (2020). The unintended side effects of bioplastics: carbon, land, and water footprints. (Link)

(2) Godsbery, C., (2020). Market review of Bioplastics, Plastics Today. (Link)

(3) Chen, G.-Q., Patel M.K. (2012). Plastics derived from biological sources: present and future: a technical and environmental review. Chemical Reviews 112(4), 2082-99. (Link)

(4) Bioplastic Feedstock Alliance. (Link)

(5) SPC Bioplastics. (Link)

(6) WWF BFA Methodology. (Link)

(7) USDA BioPreferred Policy. (Link)

(8) USDA Checkoff Programs. (Link)

(9) The Chemical Recycling of PLA: A Review. (Link)

(10) SPC Ref: Understanding the Role of Compostable Packaging in North America. (Link)

(11)Plant Based Products Council. (Link)

(12) SPC Compostable Packaging Collaborative. (Link)

(13) One Step Closer Packaging Collaborative. (Link)

(14) Braskem LCA overview. (Link)

(15) Goldstein, N. (2020) “Compost Markets In The U.S.,” BioCycle. (Link)

(16) WRAP Compostable plastic packaging guidance. (Link)

(17) WWF Position Paper: Biobased and Biodegradable Plastic (2021). (Link)