Welcome to the Plastic IQ Solutions Database,

a guide to technologies, strategies, and best practices for reducing plastic waste

CHOOSE YOUR SOLUTION

Eliminate plastic items

Minimize plastic

per item

Reuse models

Paper

Compostables

Glass

Metal

More recyclable formats

Enhance

recyclability

Bio-based content

Mechanically

recycled content

Chemically

recycled content

Reuse models

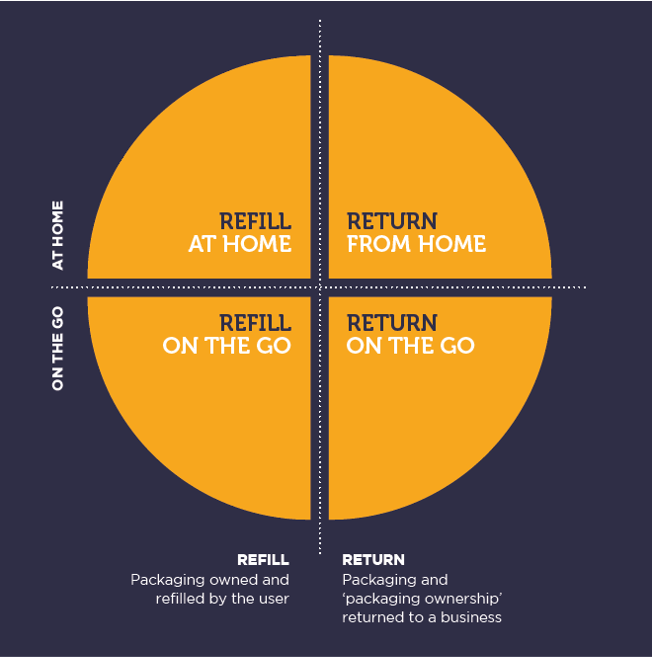

Under reuse models, reusable packaging is kept in the economy, intact, and used by consumers more than once for its original purpose (3). The reusable packaging can be offered as either a refill or a return model, often incorporating elements such as dispensers, reverse logistics, cleaning, delivery, financial incentives for customers, and subscription services. According to the Ellen MacArthur Foundation’s Upstream Innovation Guide, there are four reuse models, spanning refill models in which a customer owns the package, to return systems in which companies take back the package.

Ambition level considerations: An ambitious target (based on today’s packaging volumes) is to switch 30-50% of beverages and home and personal care products packaged in PET/HDPE bottles to durable reuse models by 2030. Since scaled reuse models can increase cost savings and efficiency, even higher targets for specific products or packaging types may be beneficial. Reuse solutions for these products range from concentrated refills to refill on the go, delivery services, and returnable bottles. For example, Coca-Cola Germany had a 40% share of reusable bottles (glass and plastic) as of 2018, and Danone sells 50% of its water volume in reusable plastic jugs.

Considerations on different packaging formats: Reuse models are most applicable for (but not limited to) the following types of packaging:

Beverages and home and personal care products currently packaged in PET/HDPE bottles switching to reuse models with durable packaging – high potential.

Dried food, snacks, and coffee currently packed in trays, jars, cups, bowls, windowed boxes, plastic bags, and pouches made of PET/HDPE/PP rigids; other polymer rigids; PE mono-material film; non-PE film, pouches, and other flexibles; or multi-material blend, switching to reuse models with durable packaging instead – medium potential.

Costs of reuse models vary significantly depending on their setup and scale. For example, one company demonstrated a one-third cost savings (compared to single-use packaging) for a refill on the go solution, while another refill on the go example has shown a one-fourth cost increase (see methodology document for costs of exemplary reuse models). For reuse models, both running costs (e.g., the production costs of the reusable packaging and reverse logistics, cleaning, and refilling) and installation costs (e.g., capital expenditure on items like bulk dispensers) need to be taken into consideration. For this reason, standardization and economies of scale are often critical for reuse models to be cost effective. In addition to user adoption, scale can be reached through either standardization within a company (e.g., standardized reusable Coca-Cola PET bottles in Latin America) or shared standards and infrastructure between industry players within or across sectors (e.g., the standardized packaging formats and shared/centralized reverse logistics and cleaning infrastructure offered by Loop or Bananeira are used by several brands) (3). Data from case studies can be found in the Method Appendix. [Link]

Switching to reuse models can drive significant reductions in greenhouse gas (GHG) emissions. Precise GHG savings vary as a function of how reuse systems are designed. An analysis by Zero Waste Europe and Reloop found that 72% of studies indicate a better environmental performance for reusable packaging, 12% show a mixed result, while in 16% of the analyzed studies, single-use packaging was found to be environmentally more favorable (4). The number of reuse cycles in practice, the weight of the reusable package, and the system layout are all key determinants of GHG emissions. In some cases (e.g., a heavy reusable package that is cycled four times or less), reuse models can even have higher GHG emissions than single-use packaging. Similarly, models with simple logistics (e.g., little or no cleaning or reverse logistics requirements) show better GHG savings relative to complex models with high transportation distances covered. In the future, low-carbon transportation, renewable energy, larger scales, and shared infrastructure could significantly improve the GHG performance of reuse models. Companies are encouraged to do further research on the actual benefits of a reuse model for their particular packaging situation. Data from case studies can be found in the Method Appendix. [Link]

Additional information is available for the four reuse models:

• Refill at home (e.g., refills delivered through a subscription service).

• Refill on the go (e.g., in-store bulk dispensers or reusable shopping bags).

• Return from home (e.g., collect reusable packages from the doorstep).

• Return on the go (e.g., return packaging to a drop-off point).

- Potential cost reductions: At scale, well-designed and successful reuse models may offer significant cost savings and drive efficiency in the supply chain. Passing cost savings on to consumers will help incentivize customers to adopt reuse, while maintaining profit margins for retailers/brands. Algramõ reports that its platform refill system, for example, not only allows firms to save 44% of costs but also offers refill products at low prices. Concentrated refill capsules, such as Everdrop’s cleaning tablets, on the other hand, can save up to 80% of transport costs by avoiding the need to transport water (3). Case studies are detailed in the Method Appendix. Companies are encouraged to complete a cost analysis of a reuse model for their packaging format.

Personalized user experience: Carefully designed reuse models can bring consumer benefits, including improved choice, more automated deliveries, and the ability for customers to mix and match flavors, personalize packaging, and choose desired quantities (2). PepsiCo’s SodaStream, for example, reduces space and travel requirements, as there is no need to carry water bottles, and accommodates user preferences by offering different flavors (3).

Stronger customer relationships: Subscription schemes for reusable packaging create long-term customer relationships and boost brand loyalty and customer retention (2). Bite toothpaste bits, for example, offers auto-refill subscription models, sending refill bites every four months. In addition, by incorporating digital offerings, firms can gather information on user preferences and improve system performance (2).

Lower emissions and plastic pollution: When well implemented, reusable packaging may reduce GHG emissions and plastic pollution compared to single-use plastic.

- Prioritize products applicable to reuse: Beverages, cleaning products, or dry food packaging can typically switch more easily to reuse models than other products (see “Considerations on different packaging formats”).

- Consider whether to offer reuse models directly or partner with a service provider: While some companies operate their own reuse models (e.g., Coca-Cola set its own reuse system in Latin America and Everdrop sells its own cleaning tablets and reusable bottles), others partner with third-party reuse service providers to take advantage of scale and know-how (e.g., Loop is a global reuse platform that works with dozens of brands). The two options have pros and cons that need to be carefully weighed. Key success factors to consider before building and operating a reuse system include:

- Reaching a critical scale to ensure cost competitiveness, especially if reverse logistics and/or cleaning is required.

- Ensuring consumer convenience by dealing with consumer barriers and providing a seamless, convenient experience for consumers. In addition to convenience, both the actual and the perceived health and safety standards of reuse systems are essential for consumer acceptance (1, 3).

- Achieving a high number of reuse cycles in practice. The number of reuse cycles over the lifetime of a reusable package is a key driver of environmental impact and economic viability, alongside factors like material choice and system layout (1, 4). Heavier reusable cups, for example, require 10 reuse cycles to break even (4). It is important to incentivize customers to return and refill as many times as possible and to monitor this indicator closely. A successful reuse model often requires a combination of using durable packaging that will not wear out and minimizing the weight of multi-use packaging (4).

- Incorporate low-carbon transport and shorten transport distances: Transportation is often the primary source of emissions for reuse models; minimize them by choosing low-carbon transport options and shorter distances wherever possible.

- Do early testing of human-centered design approaches: Avoid early-stage failures and ensure that the new systems align with the needs and preferences of users (1). Rapid prototyping and a “learn-by-doing” approach are key for reuse models as their viability often still needs to be proven, especially in new geographies and for new products.

- Watch out for unintended consequences: Reuse models can have unintended consequences, such as high water or energy consumption, high GHG emissions, or high material usage, usually driven by low reuse cycles in practice.

- Standardization: Having more universal standards for reusable and refillable packaging, as well as establishing common reverse logistics, storage, sorting, and washing, can all help to reduce costs and emissions while enhancing customer convenience, provided none of the foregoing violate applicable antitrust laws and regulations (3, 4). For example, using standard sizes that fit supply chains can make reuse models more efficient, as shown by the universal, standardized bottle from the Coca-Cola Company in Latin America.

Collaboration: Consider collaborating with other brands or sectors to achieve larger scales and lower costs with the help of streamlined logistics and transport or shared refill infrastructure (e.g., for collection or washing), provided such collaboration does not violate applicable antitrust laws and regulations (2).

Government policy and support: Policy measures can help remove market barriers for reusable packaging systems. For instance, subsidies for reusable packaging, packaging fees, or deposit return systems may help to scale up reusable packaging systems (4). Additional regulatory guidance and support, particularly around food-service regulations, may be necessary for sector growth.

Solutions and case studies

• Refill at home (e.g., refills delivered through a subscription service).

• Refill on the go (e.g., in-store bulk dispensers or reusable shopping bags).

• Return from home (e.g., collect reusable packages from the doorstep).

• Return on the go (e.g., return packaging to a drop-off point).

References and further reading

(1) Closed Loop Partners, IDEO: Bringing Reusable Packaging Systems to Life. Lessons Learned from Scaling Reusable Cups. (Link)

(2) Ellen MacArthur Foundation (2019). Reuse. Rethinking Packaging. (Link)

(3) Ellen MacArthur Foundation: Upstream Innovation. A guide to packaging solutions. (Link)

(4) Zero Waste Europe & Reloop: Reusable vs single-use packaging. (Link)