Smartweighting

Description

Smartweighting can minimize packaging while maintaining its functionality and user convenience. It involves reducing the thickness of packaging or the amount of material used while ensuring the package is still recyclable. Smartweighting, also referred to as lightweighting, has been practiced since the 1990s and is the most common strategy deployed used in water bottles. (1, 3)

At a glance

Key benefits:

- Commercial and environmental benefits can be achieved when decreasing the unit weight of packaging by reducing packaging and transportation costs (8) and greenhouse gas emissions. For example, since the early 2000s, the average weight of a half-liter water bottle has been halved (1).

- Smartweighting can reduce up to 30% of packaging without impacting recyclability. For example, ALPLA measured a 29% material reduction by lightweighting milk bottles while WRAP reports a 30% material reduction of stretch film used following simple modifications to existing equipment (5).

- Innovative technologies and materials can allow smartweight packaging. For example, alternative thermoforming methods (such as plug assist or explosive forming) can optimize the material flow in the forming dye, allowing for up to 20% thinner films, while lower-density foamed materials such as APET film weigh about 25% less than compacted films (4).

Key cautions:

- Thinner material does not necessarily mean reduced environmental impact. In particular, consideration should be given to the compatibility of smartweighted packaging with recycling systems since some ultra-lightweight packaging may be so thin that material recovery facilities can no longer sort them, negatively impacting their recyclability. Companies are urged to work with industry experts to better understand the limits of lightweight packaging during sorting for recycling.

- Following recyclability guidelines (e.g., bottle color, label, glue, or ink components) is key to achieving barrier properties, product protection (e.g., rigidity, suitability for transport), and functionality (e.g., allowing for labeling) with materials of reduced thickness (1, 4).

Where to start

- Bottles and trays often present a good opportunity to smartweight.

- Wrapping thickness can sometimes be reduced.

- Pouches can be smartweighted by reducing the amount of material used.

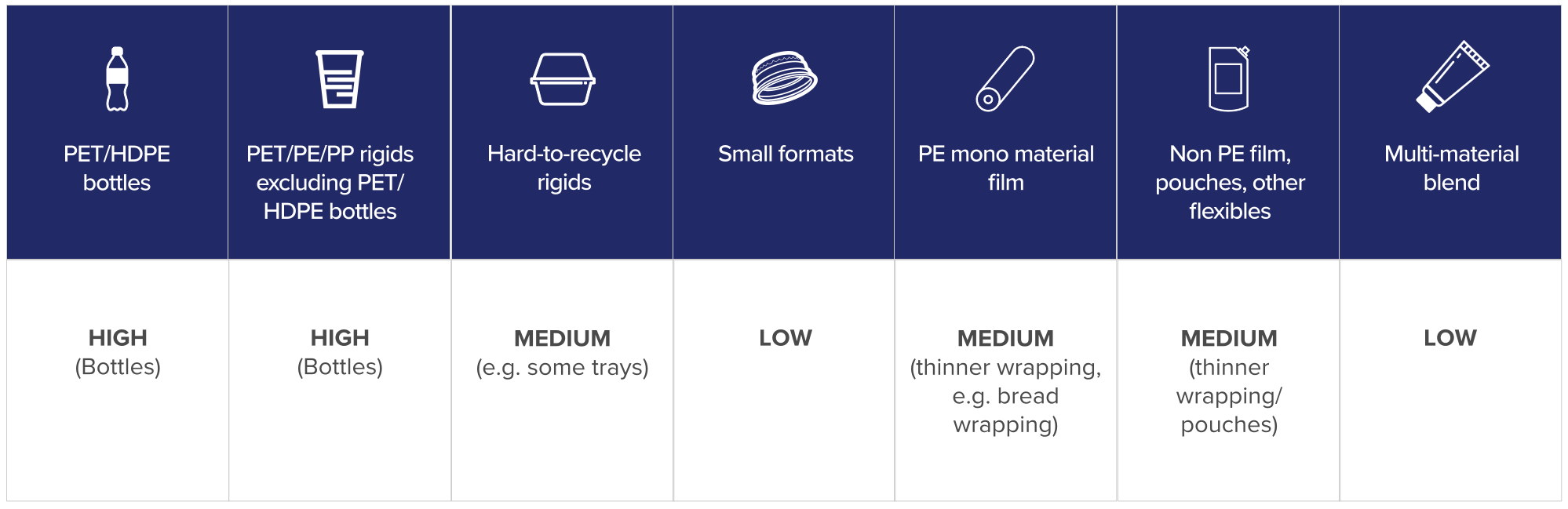

Current applicability per plastic type

Note: High in this instance implies the solution is highly applicable to the plastic type. Medium indicates potential to apply this solution to the relevant plastic type in some cases. Low implies major barriers and, generally speaking, this solution cannot be used in conjunction with the plastic type.

Solutions. and case studies

Many examples of successful reuse programs for plastic packaging are currently from outside the U.S. However, more U.S. case studies are emerging and will be included in the future. The following are used for general information and illustrative purposes and do not reflect a preference of or an endorsement by The Recycling Partnership or our affiliates or vendors.

- Fazer (Skogaholm): The Swedish bakery and bread producer reduced the size and thickness of the plastic packaging used for wrapping its bread (3).

- Ecolean Air (Aseptic) Clear pouches (globally): Durable pouches made from lightweight material (14 grams per 1 liter package) are verified to be “designed for recycling” in recycling systems for mixed polyolefin plastics. Ecolean is working to further enhance the recycling opportunities for its lightweight packaging. (Link)

- ALPLA lightweight milk bottles (UK): A 29% weight reduction of the 1-pint ECO bottle (to 12.5 grams) was achieved with an increased proportion of food-approved postconsumer recycling material, creating economic savings and environmental benefits while meeting functionality requirements. (Link)

- LINPAC super-lightweight 100% recyclable mono-material trays for meat and poultry (UK): These trays have a lower carbon footprint than the previous design, retaining high levels of performance and quality, and using a sealant technology to remove the need for laminate PE base film. (Link)

Reports and References

(1) Packaging Europe (2017). Lightweighting and Recycling. (Link)

(2) Ellen MacArthur Foundation: Upstream Innovation. A guide to packaging solutions. (Link)

(3) European Economic and Social Committee: Recycling food packaging & food waste in plastics revolution. (Link)

(4) WRAP: Minimum thickness of plastic bottles to be recycled. (Link)

(5) WRAP (2009). Efficient use of resources in breakfast cereal design packaging. (Link)